Skid Steer Loader vs. Track Loader

Skid Steer Loader vs. Track Loader: Key Differences

Track loaders and skid steers fit many of the same applications, but each machine is built differently, optimizing its movement and functions for different types of terrain. You can get the most out of your equipment and prolong its life span when you rent or purchase the right machine for your specific application and work site.

What Is a Skid Steer?

A skid steer is a multipurpose machine, but its primary purpose is digging. Skid steers are compact and contain arms to hold various attachments. Operators often refer to skid steers as “wheel loaders” because each skid steer operates on four wheels.

Skid steers differ in size and come in the following frames:

- Small: Small-frame skid steers are lighter than other models, making them the most maneuverable and the best fit for landscaping projects. A small-frame skid steer weighs less than 1,750 pounds and has a horsepower below 50.

- Medium: Medium-frame skid steers help operators complete heavy-duty tasks in small spaces because they weigh between 1,750 and 2,200 pounds and operate on 50-70 horsepower.

- Large: Large-frame skid steers provide the most power, making them an excellent option for excavation and demolition tasks. A large-frame skid steer weighs over 2,200 pounds, and its horsepower exceeds 70.

A skid steer’s size determines its rated operating capacity (ROC), which is the maximum weight the machine can lift safely without tipping. Skid steers typically have a 50% ROC, meaning they can lift 50% of their total weight.

A skid steer can also have one of two different types of lift capacities. A radial lift capacity is ideal for moving loads at or close to ground level. If you need to shift terrain or move dirt, a skid steer with radial lift capacity is the perfect choice. A skid steer with vertical lift capacity enables you to reach taller spaces and perform higher load movements.

What Is a Track Loader?

A track loader is very similar to a skid steer because it’s a compact machine with two arms to hold various attachments. However, a track loader moves via rubber or steel tracks, making it heavier and more stable than a skid steer. A track loader has a 35% ROC, which means it can lift 35% of its total weight without tipping.

Track loaders come in small, medium and large frames, and their weight differs according to the following size ranges:

- Small: A small track loader weighs approximately 2,000 pounds.

- Medium: Medium track loaders weigh approximately 2,200 pounds.

- Large: A large track loader weighs approximately 3,000 pounds.

How Skid Steer Loaders and Track Loaders Differ

The main difference between track loaders and skid steers is their movement and how this affects their performance on different work sites. Choosing the right machine for your project or company depends on the terrain of your job site.

Skid steers are faster and easier to maneuver on flat, solid terrain such as asphalt and concrete. A skid steer can move across a paved or flat surface swiftly, but it cannot handle softer ground or uneven terrain.

If you work on uneven terrain, such as hills or wooded areas, a track loader can meet your needs with little soil disruption. Asphalt and hard ground can gradually damage a track loader’s rubber tracks, but this machine provides excellent performance on uneven ground.

Buying Guide: Track Loader vs. Skid Steer

You must consider a machine’s costs and how well it can handle your specific applications before you make a decision. The following factors are essential when choosing between these machines:

Performance and Efficiency

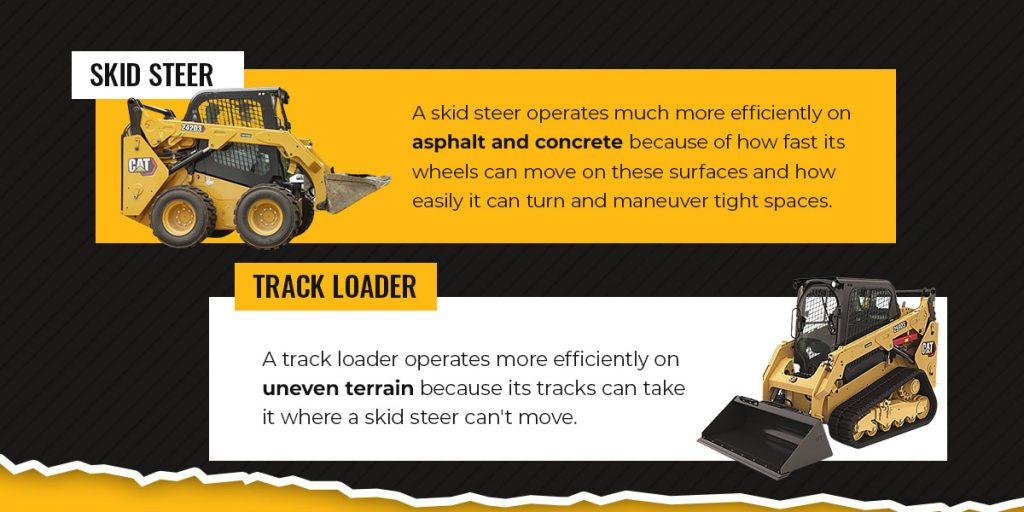

Due to how track loaders and skid steers perform on different terrains, the option you choose can affect efficiency.

A skid steer operates much more efficiently on asphalt and concrete because of how fast its wheels can move on these surfaces and how easily it can turn and maneuver tight spaces. A track loader operates more efficiently on uneven terrain because its tracks can take it where a skid steer can’t move.

Choosing the right machine enables you to complete jobs quickly with less labor. For example, it may take hours to complete a job with a track loader on a concrete surface, but you can complete it within an hour or less using a skid steer.

Durability and Easy Maintenance

A skid steer or track loader’s performance on different terrain also affects its durability and how much maintenance it requires. Since hard surfaces can wear down a track loader’s rubber tracks faster than a skid steer’s wheels, a skid steer can last longer than a track loader on job sites containing concrete and asphalt terrain.

Similarly, a track loader offers more durability and longevity when you use it for tasks involving uneven and soft terrain. Basing your purchase or rental decision on your work site’s conditions helps minimize the amount of maintenance you must complete.

Upfront Costs and Long-Term Value

Track loaders typically have a higher upfront cost than skid steers. However, it’s important to consider a machine’s value over its cost.

If longevity is your top concern, a track loader may be your ideal option. Tracks typically wear slower and require fewer replacements than wheels, increasing their long-term value. In comparison, a skid steer offers more long-term value if you primarily work on hard surfaces.

Investing in the right equipment for your applications increases your return on investment because it helps your equipment withstand your work conditions better and last longer.

Ownership Costs

Skid steers and track loaders typically have similar preventative maintenance costs because they have similar engines. You may notice they differ the most when it comes to repairing and replacing parts. Skid steer parts are typically more affordable to repair and replace. Repair and replacement costs for track loaders vary based on track type.

Popular Attachments for Skid Steers and Track Loaders

The following attachments are popular for skid steers and track loaders:

- Drum mulchers

- Stump grinders

- Tillers

- Brush cutters

- Root rakes

- Tree pullers

- Augers

- Dozer blade

- Trenchers

- Backhoes

- Buckets

- Grapples

- Forks

- Snowblowers, snow blades and snow pushers

- Demolition attachments such as shears and hydraulic hammers or breakers

The right attachments depend on your specific applications. When choosing forestry and land clearing attachments, you must consider what type of materials you need to move. For example, root rakes are ideal for weeds and vegetation, while drum mulchers provide the power necessary to break up and move heavier materials such as trees and brush.

It’s also important to choose the right attachment size for your application. For example, using a small backhoe attachment is a cost-effective way to complete smaller jobs.

Trust Mustang Cat® With Your Equipment Needs

Mustang Cat® can help you decide between a skid steer and track loader based on your project needs and work site conditions. We provide Southeast Texas with high-quality equipment rental, parts, services and sales. Contact Mustang Cat to learn more, rent a compact skid steer or track loader, schedule service, or order parts.