Capabilities of Dozers: Types, Parts and Their Uses

There are very few vehicles as useful and versatile as the bulldozer. Power, adaptability and reliability are the key features that make these machines so invaluable.

This guide will explore the uses of bulldozers in different industries, including construction, agriculture and mining. Looking at the popular kinds of bulldozers, their components and the work they can complete will provide insight into why these are essential pieces of equipment.

Introduction to Dozers

Bulldozers are adaptable earthmoving machines primarily used for pushing, digging, leveling and grading. Though popular in construction, bulldozers are also often used in agriculture, mining and landscaping. They are crucial in preparing construction sites, maintaining roads and infrastructure, reclaiming land, controlling erosion, clearing debris and more.

Equipped with a large metal blade at the front, they are adept at moving soil, sand, gravel and other loose materials. Their powerful engines and robust designs allow them to easily handle heavy-duty tasks. What makes bulldozers even more useful is the different specialized tools that can be attached to them. With these attachments, the dozer can be fully customized to suit specific jobs.

Bulldozer Types and Their Uses

Many types of bulldozers exist, but two in particular stand out the most. These are crawler dozers and wheel dozers:

Crawler Dozers

Crawler dozers are commonly used for several reasons. These dozers operate on tracks, making them less likely to slip when working on wet and muddy terrain or uneven surfaces. Their heavy weight distributes pressure evenly, minimizing ground damage.

Crawlers have powerful engines, which makes them ideal for construction projects. They are best used for clearing, grading and handling heavy materials. Their versatility is further enhanced by the ability to equip various blades and attachments.

Wheel Dozers

Unlike crawler dozers, wheel dozers use wheels. Wheels make them faster but less stable on steep slopes. Wheel dozers have articulated steering, which provides excellent maneuverability, especially in tight spaces and urban environments.

Wheel dozers offer several advantages that make them valuable assets in various industries. Firstly, their mobility and fast speeds make them ideal for moving between job sites. These dozers are also useful for traveling long distances. This agility and endurance allow for quicker response times and increased productivity.

With a lower initial cost than crawler dozers, they are more accessible for small businesses and operations with budget constraints.

Different Parts of a Bulldozer

Bulldozers come with a selection of parts and attachments to help users accomplish a variety of tasks.

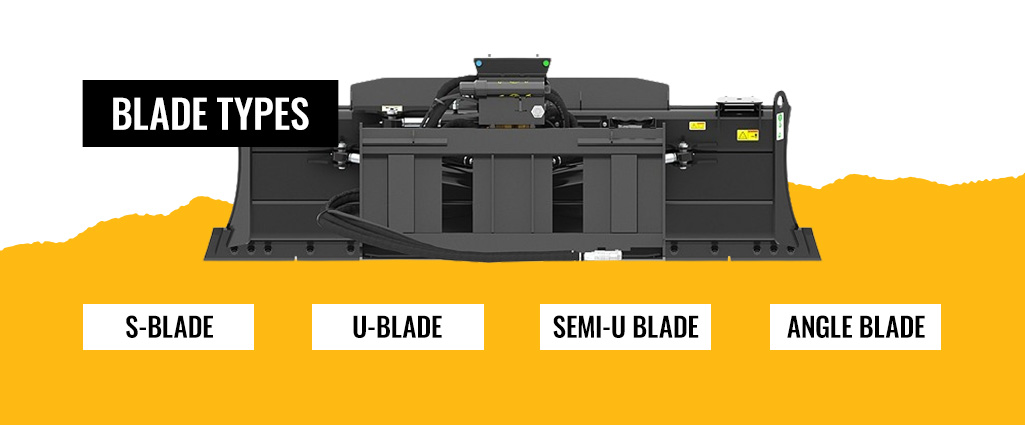

Blade Types

Bulldozers can be equipped with various blade attachments to suit different tasks and terrains:

- S-blade: This is the most common blade type. Its straight edge makes it ideal for pushing and spreading soil, gravel and debris. It provides a flat surface for grading and leveling.

- U-blade: These curved blades can hold more material than straight blades, so they’re best for heavy-duty pushing and dozing applications. Moving large volumes of earth and snow to clear worksites is best done with a U-blade attachment.

- Semi-U blade: Combining elements of the straight and U-blade makes this a versatile attachment. They are useful for various tasks like grading, pushing and loading.

- Angle blade: Angle blades can angle around 30 degrees to the left or right. They’re efficient for pushing and spreading materials while also enabling the dozer to perform other tasks like shaping ditches and embankments.

Undercarriage Components

The undercarriage of a bulldozer consists of several key components used to support and propel the machine.

- Tracks or wheels: Provide traction and stability for the bulldozer and vary based on bulldozer weight and size

- Track frames: Support and distribute the machine’s weight

- Rollers: Guide and support the tracks as they move

- Idlers: Assist in guiding the tracks and maintaining traction

- Sprockets: Engage with the track links to propel the dozer

Special Features

These are a few examples of special features that can enhance what a bulldozer can do.

- Ripper attachments: Like blade attachments, these attachments break up hard soil, rock and pavement for excavation and site preparation.

- Adjustable blade tilt: This feature allows for precise control and grading of materials.

- Hydraulic systems: Hydraulic systems enable precise control of blades and other attachments.

- Automated features: Some models offer automation for blade control and guidance to increase productivity and accuracy.

Applications of Bulldozers in Various Fields

These machines can be used in a variety of industries for earthmoving tasks, though three main fields use bulldozers most often.

Bulldozers in Construction

Bulldozers play a crucial role in construction projects due to their versatility and power. In construction, they are used for:

- Earthmoving: Clearing and leveling land, excavating foundations and backfilling trenches

- Grading: Creating level surfaces and slopes for roads, building pads and landscaping

- Material handling: Pushing, spreading and compacting materials like gravel and soil

- Demolition: Knocking down structures and clearing debris

- Road construction: Building and maintaining roads, highways and parking lots

- Site preparation: Clearing vegetation, rocks and obstacles before construction begins

- Landscaping: Shaping terrain and creating drainage features

Bulldozers in Agriculture

Bulldozers serve the following purposes in the agriculture industry:

- Land clearing: Removing trees, stumps and brush to prepare fields for planting

- Field leveling: Grading land to ensure even irrigation and optimal crop growth

- Drainage construction: Excavating ditches and trenches to manage water flow and prevent flooding

- Terracing: Creating land terraces on hillsides to minimize erosion and maximize arable land

- Silage pit construction: Excavating and shaping pits for storing animal feed

- Irrigation canal construction: Digging and maintaining irrigation channels for crop watering

- Manure management: Handling and spreading manure for soil enrichment

Bulldozers in Mining

In mining operations, bulldozers are invaluable assets, offering robustness and adaptability. Bulldozers are capable of helping operations in the following ways:

- Overburden removal: Clearing layers of soil and rock to access mineral deposits

- Pit development: Excavating and shaping open-pit mines to reach ore bodies

- Haul road construction: Building and maintaining roads for transporting materials and equipment within a mine site

- Stockpile management: Creating and shaping piles of extracted materials for storage and processing

- Reclamation: Restoring mined areas by reshaping terrain and covering with topsoil for vegetation restoration

Get the Dozer You Need in Houston and Southeast Texas From Mustang Cat®

At Mustang Cat®, we provide machines you can rely on for any project. Whether you need a sturdy machine for mining and construction or an adaptable tool for landscaping and agriculture, we have what you need. Explore our selection to find new bulldozers or locate a rental model to help you with your next big job.

Our team specializes in providing unparalleled efficiency and performance. We’ll help you determine the best dozer and attachment types to tackle your most complex tasks. Contact us to explore all the options we can offer you and request a quote for the machines you need today.