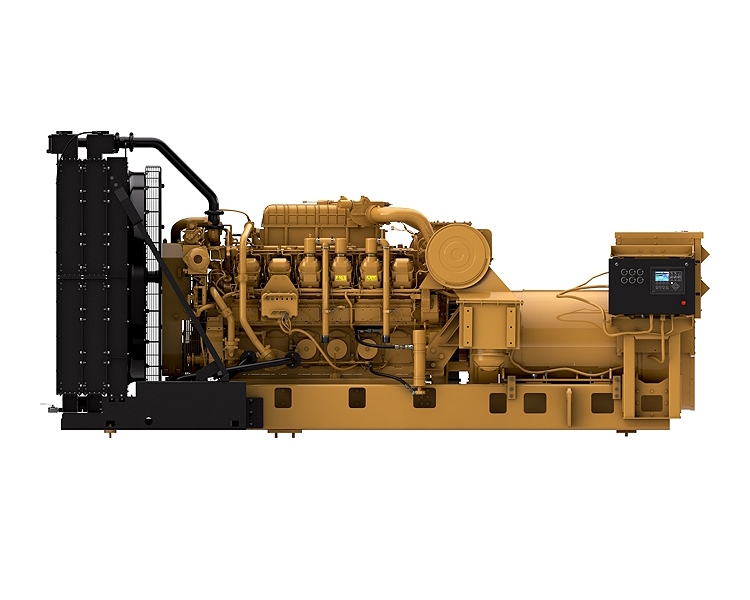

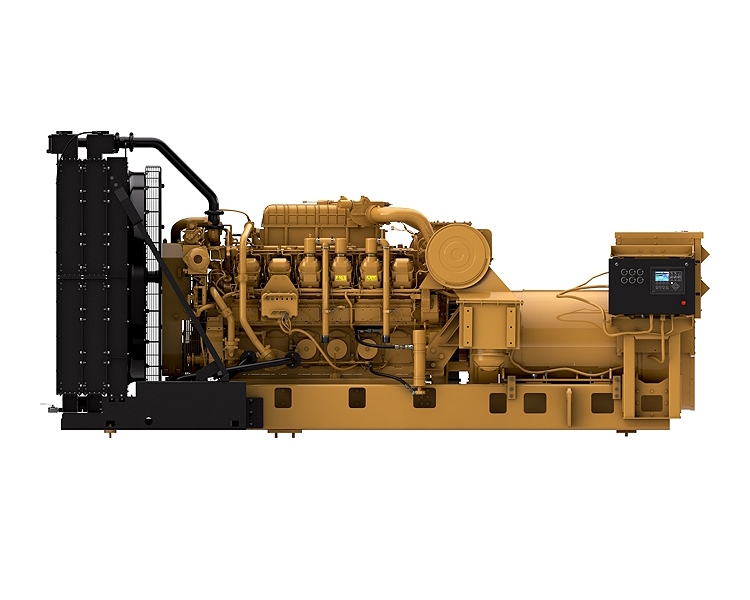

3512C (HD) Land Electric-Drive Drilling Module

Oil and gas drilling is a complex task that requires specialized power generation equipment. Cat 3500 power modules are specifically designed for drilling operations of electric AC rigs. They combine decades of field experience of the 3500 platform with the latest electronics to ensure highest performance, low emissions, and simplified operator interface. Cat power modules are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. 3512C (HD) land drilling power modules rating: 1245 ekW (1780 kVA) @ 60 Hz (1200 rpm). Meets U.S. EPA Tier 2 equivalent emission standards. Available using U.S. EPA Flexibility and for other regulated and non-regulated areas.

Engine Specifications

Minimum Rating

Maximum Rating

Emissions

Bore

Oil Change Interval

Weight

Generator

Aspiration

Displacement

Stroke

Generator Set Control

Fuel System

Voltage

Engine Control and Protection

Dimensions

Length

Width

Capacity for Liquids

Lube Oil System - Refill

Cooling System - Engine

Standard Equipment:

-

- Air Inlet System

-

- Corrosion-resistant aftercooler core

- Air Inlet shutoff

- Regular duty air cleaner

-

- Control System

-

- ADEM A3 ECU, left-hand mounted

- Direct rack control 0-200 mADC, space heater and jacket water heater connection and controls or

- Cat Digital Voltage Regulator (DVR), includes reactive droop capability, 3-phase voltage sensing, kVAR/PF modes, RFI suppression, min/max exciter limiter and exciter diode monitor, space heater and jacket water heater connection and controls, temperature monitoring for 6 stator RTDs and 2 bearing RTDs via J1939

-

- Cooling System

-

- Separate-circuit aftercooled

- Outlet controlled jacket water thermostat

- Jacket water pump - gear driven

- Dual outlet

- Aftercooler water pump - gear driven

- Aftercooler water thermostat

-

- Exhaust System

-

- Dry exhaust manifold

- Dual turbochargers, water cooled bearings

- Exhaust adapter, 297 mm I.D. to 340 mm I.D. (11.7 in to 13.4 in)

- Weldable flange, 360 mm I.D. (14.2 in)

-

- Flywheel And Housing

-

- SAE No. 00 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

-

- Fuel System

-

- Fuel filter simplex (LH) with priming pump (LH)

- Fuel transfer pump

- Fuel return line with flexible connection

- Electronic unit injectors

- Fuel priming pump

-

- Instrumentation

-

- Emergency stop button

- Analog gauges:

- Service port connector

- Customer connection terminal blocks

-

- Emcp 4.3 Control Panel

-

- 140 mm (5.5 in) Graphical Display

- Communication

- Controls

- Generator Set Protection

- Outputs

- Inputs

- Other Features

-

- Lubrication System

-

- Crankcase breather

- Oil cooler

- Shallow oil pan

- Oil drain extension, 2 in NPT female connection

- Simplex oil filter

-

- Mounting System

-

- 4.19 m (165 in) length, 412 mm (16.2 in) height tubes, 1.18 m (50.5 in) wide

- Viscous damper drive line coupler

-

- Power Take-offs

-

- Accessory drive

- Lower LH front (available for PTO usage)

- Front housing, two-sided

-

- Protection System

-

- Engine alarms, derate, and shutdown in abnormal operation

-

- Starting System

-

- TDI air starting motor, RH - 1034 kPa (150 psi)

- LH control air silencer

-

- General

-

- Paint - Cat yellow

- Vibration damper and guard

- Lifting eyes

- Lift and cable two provisions

Optional Equipment:

-

- Air Inlet System

-

- Heavy duty air cleaner

- Remote air inlet adapter - rectangular

- Remote air inlet adapter - round

-

- Control System

-

- Load sharing governor, 2301A

- Load sharing module

- Governor conversion to 0-200 mA direct rack control

-

- Cooling System

-

- Radiator options:

- Coolant level sensor

- Coolant conditioner

-

- Exhaust System

-

- Exhaust flexible fitting, 318 I.D. mm (12.5 in)

- Elbow, 305 mm (12 in)

- Muffler 305 mm (12 in), non spark arresting

- Muffler, 356 mm (14 in), spark arresting, includes companion flanges, clean-out box, and spark box

- Muffler, 305 mm (12 in), spark arresting, includes companion flanges, clean-out box, and spark box

-

- Fuel System

-

- Custom fuel filter

- Primary fuel filter

- Primary fuel filter with water separator

-

- Generator Attachments

-

- Barrel-mounted petroleum terminal box with air filter and pressure differential switch

- Barrel-mounted petroleum terminal box

- Current droop transformer

- Cable access box

- Low voltage extension box

- Current sensing transformers (3)

- Bearing temperature detectors

-

- Instrumentation

-

- Communications module PL1000T

- Communications module PL1000E

- Thermocouples installed, one per cylinder

-

- Lubrication System

-

- RH installed centrifugal oil filter

- Crankcase fumes disposal

- Oil level regulator

-

- Mounting System

-

- 7.62 m (25 ft) outer base

- 9.14 m (30 ft) outer base

- 12.19 m (40 ft) outer base

- Package isolator supports (3), for mounting inner base to customer-supplied base

- Custom base

-

- Power Take-off

-

- Alternator, 24V, 60A

- Crankshaft pulley

-

- Protection System

-

- Explosion relief valves (3)

- Metal particle detector switch

- Metal particle detector with annunciator

-

- Starting System

-

- Custom starting motor

- Air pressure regulator

-

- General

-

- LH installed engine barring group

- Jacket water heater, UL recognized, 120-240V, single phase, 6 kW, LH and RH mounted

- Jacket water heater, UL recognized, 120-480V, single phase, 12 kW, LH and RH mounted

- Jacket water heater lines

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.