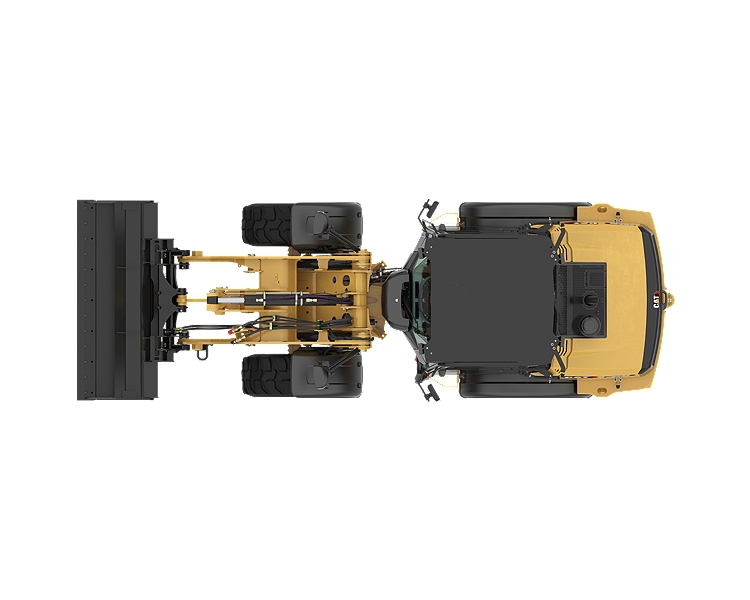

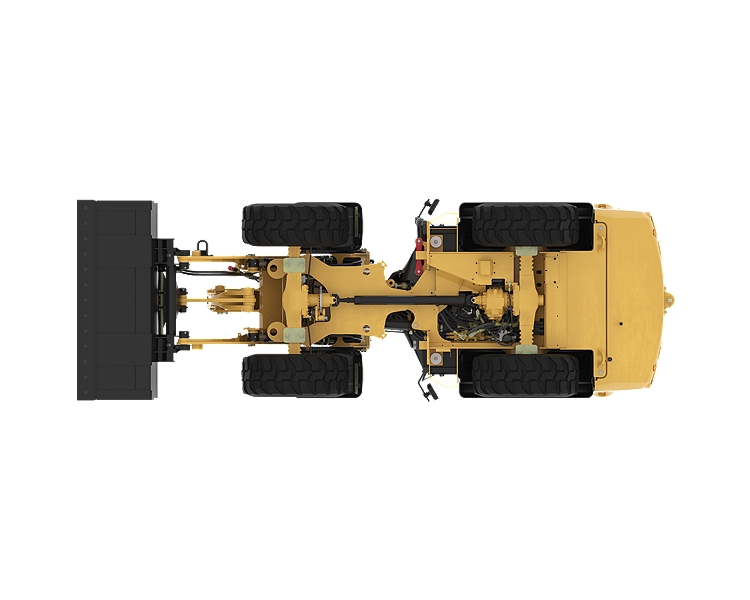

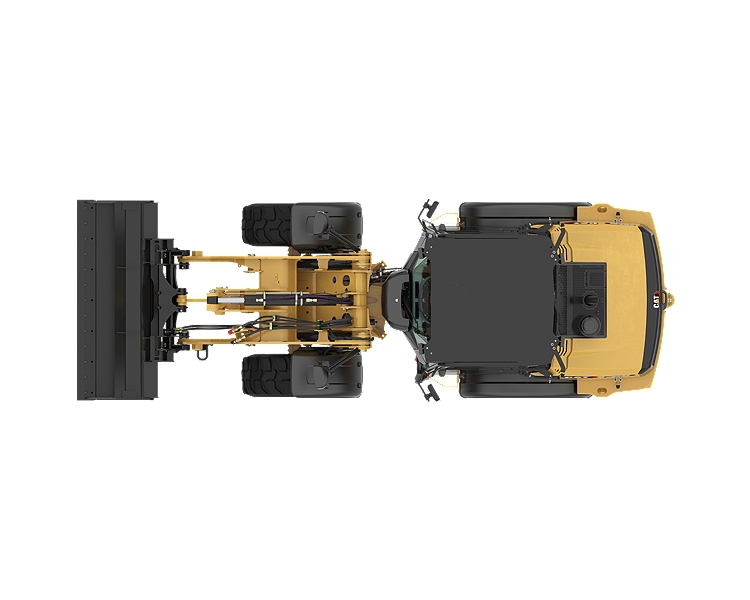

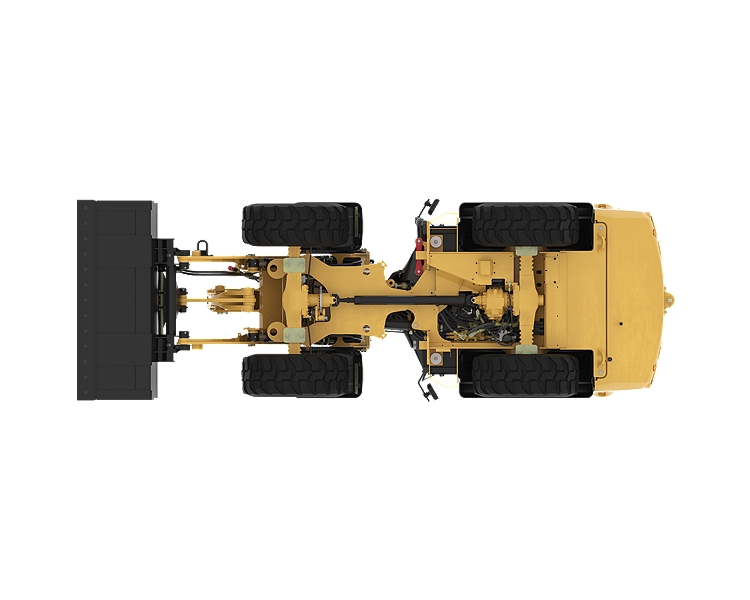

906M Compact Wheel Loader

The Cat® 906M Compact Wheel Loader delivers high performance with outstanding versatility. On-the-go operator tuned hydraulics and drive train adjust the machine’s response to the task at hand. Low sound levels, large spacious cab and intuitive controls keep you working comfortably all day long.

Engine

Maximum Gross Power

Engine Model

Maximum Gross Power - ISO 14396

Maximum Gross Power - ISO 14396 (metric)

Rated Net Power - 2,400 rpm - SAE J1349

Rated Net Power - 2,400 rpm - ISO 9249

Maximum Gross Torque - ISO 14396

Maximum Net Torque - ISO 9249

Bore

Displacement

Stroke

Note (1)

Note (2)

Note (3)

Note (4)

Note (5)

Note (6)

Emissions

Weights

Operating Weight

Note

Buckets

Bucket Capacities

Bucket Capacities - ISO Coupler

Bucket Capacities - SSL Style Coupler

General Purpose

Light Material

Multi-Purpose

Grapple

Note

Service Refill Capacities

Cooling System

Fuel Tank

Engine Oil

Hydraulic Tank

Hydraulic System - Including Tank

Transmission - Gear Box

Loader Hydraulic System

Maximum Flow - Implement Pump

Maximum Flow - Implement Pump - Auxiliary Function Standard Flow

Maximum Flow - Implement Pump - Auxiliary Function High Flow

Maximum Working Pressure - Implement Pump

Relief Pressure - Tilt Cylinder Head

Relief Pressure - Tilt Cylinder Rod

3rd Function Maximum Working Pressure

Boost Flow Maximum Pressure

Lift Cylinder, Double Acting - Bore Diameter

Lift Cylinder, Double Acting - Rod Diameter

Lift Cylinder, Double Acting - Stroke

Tilt Cylinder, Double Acting - Bore Diameter

Tilt Cylinder, Double Acting - Rod Diameter

Tilt Cylinder, Double Acting - Stroke

Hydraulic Cycle Time - 1,800 rpm - Raise, Ground Level to Maximum Lift

Hydraulic Cycle Time - 1,800 rpm - Dump, at Maximum Lift Height

Hydraulic Cycle Time - 1,800 rpm - Float Down, Maximum Lift to Ground Level

Hydraulic Cycle Time - 1,800 rpm - Total Cycle Time

Hydraulic Cycle Time - 1,000 rpm - Raise, Ground Level to Maximum Lift

Hydraulic Cycle Time - 1,000 rpm - Dump, at Maximum Lift Height

Hydraulic Cycle Time - 1,000 rpm - Float Down, Maximum Lift to Ground Level

Operating Specifications

Tipping Load - Straight - ISO 14397-1

Tipping Load - Full Turn - ISO 14397-1

Full Turn Tipping Load

Clearance - Full Lift and 45° Dump

Reach - Full Lift and 45° Dump

Steering Articulation Angle - Each Direction

Rated Bucket Capacity

Dimensions with Bucket (Approximate) - Standard Lift - With ISO Coupler

Height - Ground to Cab**

Height - Ground Clearance**

Length - Wheel Base

Length - Overall*

Reach - Bucket at 45°*

Dig Depth**

Clearance - Bucket at 45° *

Clearance - Level Bucket**

Height - Bucket Pin**

Departure Angle

Turning Radius - Over Bucket

Turning Radius - Inside of Tires

Width - Bucket

Width - Tread Center

Machine Width

Articulation Angle

Dump Angle at Full Lift

Operating Weight

Note (1)

Note (2)

Note (3)

Dimensions with Bucket (Approximate) - Standard Lift - With SSL Coupler

Height - Ground to Cab**

Height - Ground Clearance**

Length - Wheel Base

Length - Overall*

Reach - Bucket at 45°*

Dig Depth**

Clearance - Bucket at 45° *

Clearance - Level Bucket**

Height - Bucket Pin**

Departure Angle

Turning Radius - Over Bucket

Turning Radius - Inside of Tires

Width - Bucket

Width - Tread Center

Machine Width

Articulation Angle

Dump Angle at Full Lift

Operating Weight

Note (1)

Note (2)

Note (3)

Cab

ROPS

FOPS

Note (1)

Note (2)

Note (3)

Tires

Note (1)

Note (2)

Note (3)

Note (4)

Option (1)

Option (2)

Option (3)

Option (4)

Option (5)

Option (6)

Option (7)

Drive Train

Forward - Range 1

Forward - Range 2

Forward - High Range

Reverse - High Range

Reverse - Range 1

Reverse - Range 2

Steering

Steering Articulation Angle - Each Direction

Steering Cylinder, Double Acting - Bore Diameter

Steering Cylinder, Double Acting - Rod Diameter

Steering Cylinder, Double Acting - Stroke

Nominal Flow - Steering Pump

Maximum Working Pressure - Steering Pump

Maximum Steering Torque - 0° (Straight Machine)

Maximum Steering Torque - 39° (Full Turn)

Steering AC Cycle Times - Full Left to Full Right - 2,620 rpm

Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left

Standard Equipment:

-

- Transmission And Hydraulics

-

- 18° frame oscillation, 78° articulation

- Demand based cooling fan

- Hydrostatic drive

- Loader arm float function

- Parallel lift Z-bar loader

- Proportional auxiliary hydraulic circuit

- Transmission, 20 km/h (12.4 mph) with heavy duty axles

- Transmission inching function

-

- Engine

-

- Cat C3.3B DIT EU Stage V/U.S. EPA Tier 4 Final engine.

- Cat extended life coolant

- Closed circuit breather

- Easy quick release fuel filter/water separator

- ECO mode

- Engine oil drain valve (non-spill ECO drain)

- Lockable engine compartments

- Two stage air cleaner with visual indicator

-

- Electrical

-

- Alternator 90 amp

- Battery disconnect switch

- Cab mounted fuse panel

- Engine cold starter aid

- Heavy duty battery, 12V

- Service point connector for electronic diagnosis (Cat Electronic Technician™)

- Reversing alarm

-

- General

-

- E-coat paint primer

- Pressure test points

- Recovery hitch and pin

- Scheduled Oil Sampling S·O·SSM ports

-

- Operator Environment

-

- Adjustable internal mirror

- Adjustable wrist rest

- Auxiliary power sockets

- Coat hook

- Cup holder

- Digital service hour meter

- Easy clean cab floor

- Gauges: fuel hydraulic temperature, coolant temperature, speedometer

- Multifunction joystick with direction control

- On board digital display cluster

- Operator station on isolation mounts

- Retractable seat belt

- ROPS and FOPS certified canopy/cab

- Sound suppression

- Sun visor

- Suspended brake/accelerator pedals

- Suspension seat

- Two doors (enclosed cab)

- Two external knock back mirrors

- Warning indicators for major systems

- Wiper/washer front and rear (enclosed cab)

- Warnings: master, park brake, hydraulic oil pressure, engine oil pressure, coolant temp, electrical system, hydraulic filter bypass

Optional Equipment:

-

- Transmission And Hydraulics

-

- 100% differential lock on both axles, selectable on the move

- Adjustable speed control (creeper control)

- Adjustable high stat response settings

- Electronic throttle lock

- Ride control

- Rimpull control

- Speeder, 35 km/h (21.7 mph) with secondary steering

-

- Engine

-

- Engine block heater 120V

- Precleaner for engine air filter

-

- Electrical

-

- Machine Security System (MSS)

- Magnetic rotating beacon

- Halogen working lights, two front and two rear

- LED working lights, two front and two rear

- Work tool wiring harness

-

- General

-

- Custom color

- Rear light guards

- Tire options including heavy duty tires

-

- Fluids

-

- Cat extended life coolant (–50° C/–58° F)

-

- Loader

-

- Adjustable implement modulation

- High flow auxiliary hydraulics with pressure relieving quick disconnect manifold

- Load check valves

- Return To Dig tool positioner

-

- Work Tools

-

- For all work tool options, consult your local Cat dealer

-

- Operator Environment

-

- Air conditioning

- Cabin light

- Cat Radio/FM/DAB+/Bluetooth/Aux/Mic/Phone/USB

- Comfort cab includes: cloth suspension seat, heated rear window, sliding left window and radio ready

- Open canopy: fixed steering column, coat hook, sun visor (North America only)

- Deluxe cab includes: Comfort cab options plus heated cloth air suspension seat with lumbar support and right sliding window

- Heated rear window (enclosed cab)

- Heater with window side and feet vents (enclosed cab)

- Radio ready kit including speakers (enclosed cab)

- Rear blind

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.