785 Mining Truck (LRC, Tier 4 Final / EU Stage V)

The 785 Large Mining Truck was Caterpillar’s first entry into the mining industry more than three decades ago and has been a proven performer on sites around the world ever since. And now it’s the first to combine a game-changing level of efficiency with industry-leading physical availability to deliver the next generation of productive hauling. It all starts with the operator, who sits in a state-of-the-art environment designed for efficiency and equipped with features that increase comfort, automate functions, provide real-time information and boost confidence. The 785 also delivers significant improvements in serviceability and reliability, enhanced connectivity and easier technology integration. These improvements — and more — take an already proven truck to the next level of productivity.

Weights - Approximate

Nominal Rated Payload (33.00R51 Tires)

Rated Gross Machine Weight (33.00R51 tires)

Nominal Rated Payload (36.00R51 Tires)

Rated Gross Machine Weight (36.00R51 tires)

Chassis Weight (33.00R51 Tires)

Chassis Weight (36.00R51 Tires)

Body Weight

Note (1)

Note (2)

Note (3)

Engine

Gross Power - SAE J1995

Net Power - SAE J1349

Engine Model

Emissions Rating

Bore

Stroke

Displacement

Note (1)

Note (2)

Note (3)

Weight Distributions - Approximate

Front Axle - Empty

Rear Axle - Empty

Front Axle - Loaded

Rear Axle - Loaded

Note

Final Drives

Type

Differential Ratio

Planetary Ratio

Total Reduction Ratio

Tires

Standard Tire

Optional Tire

Rims

Note (1)

Note (2)

Braking System

Service Brakes

Front Wet Disc Brake Surface Area

Rear - Wet Disc Brake Surface Area

Standards

Parking Brake

Capacity - MSD II - 100% Fill Factor

Struck

Heaped (SAE 2:1)

Note

Body Hoists

Type

Pump Flow - High Idle

Relief Valve Setting - Raise

Body Raise Time - High Idle

Body Lower Time - Float High Idle

Body Lower Time - Float Low Idle

Body Power Down- High Idle

Suspension

Type

Effective Cylinder Stroke - Front

Effective Cylinder Stroke - Rear

Rear axle - Oscillation

Service Refill Capacities

Fuel Tank

Diesel Exhaust Fluid Tank

Cooling System

Crankcase

Front Wheels - Each

Differential - Final Drives

Steering Tank

Steering System - Includes Tank

Brake/Hoist Tank

Brake Hoist System - Includes Tank

Torque Converter - Transmission System - Including Sump

Cab

Air Conditioning

Heater / Defroster

Note

ROPS Standards (1)

FOPS Standards

Steering

Steer Angle

Turning Diameter - ISO 7457:1997 (33.00R51 tires)

Steering Standards

Dimensions (All dimensions are approximate. MSD II Body, 33R51 tires, unloaded machine.)

Height - Top of ROPS

Overall Body Length

Inside Body Length

Overall Length

Wheel Base

Rear Axle - Tail

Ground Clearance

Dump Clearance

Loading Height - Empty

Inside Body Depth - Maximum

Overall Height - Body Raised

Operating Width

Centerline Front Tire Width

Engine Guard Clearance

Overall Canopy Width

Outside Body Width

Inside Body Width

Front Canopy Height

Rear Axle - Clearance

Centerline of Rear Dual Tire Width

Overall Tire Width

Transmission

Forward - 1

Forward - 2

Forward - 3

Forward - 4

Forward - 5

Forward - 6

Reverse

Top Speed - Loaded

Note

Standard Equipment:

-

- Electrical

-

- 24V electrical system, low maintenance batteries (2) 93 amp-hour

- Alarm, backup

- Brushless alternator, 225 amp

- Ground accessible power control box: Ethernet VIMS™ port and VIMS lamp; Engine starter; transmission and battery lockouts

- Jump start/battery charge receptacle

- LED payload indicator lamps

- LED Lighting system: Back-up and hazard lights, Curb lights, (one) RH side, (one) LH side, Turn signals (front and rear), Engine compartment lights, Headlights with low-high beam selector, Ladder light and service deck lights, Stop/tail lights

-

- Fluids

-

- Extended Life Coolant to — 35° C (— 30° F)

-

- Operator Environment

-

- 5V USB charging port

- 12V auxiliary power connection

- Cup holders

- Diagnostic connection port COM3 and Ethernet

- Delayed Engine Shutdown

- Dome courtesy light and map lights

- Entertainment radio ready: Speakers, Optional Antenna (AM/FM/WB/satellite radio), Radio mounting provisions and 12V power supply

- Fire suppression ready

- Floor mat, multi-piece & replaceable

- Gauges and indicators panel: Critical oil and coolant temperatures; Fuel and DEF level (if applicable); Engine system, brake and transmission fault indicators; Operator selectable max. machine speed by rotary dial; Speedometer, Tachometer

- Heated mirrors, right and left

- Hoist, body control

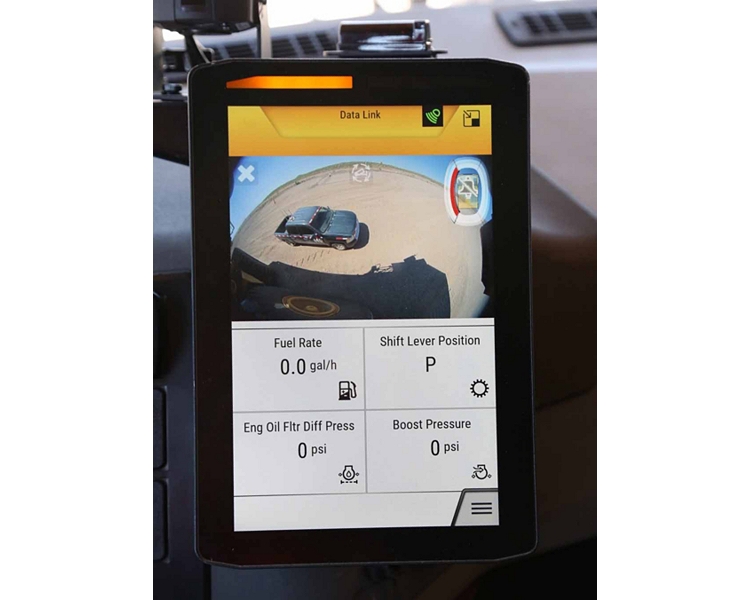

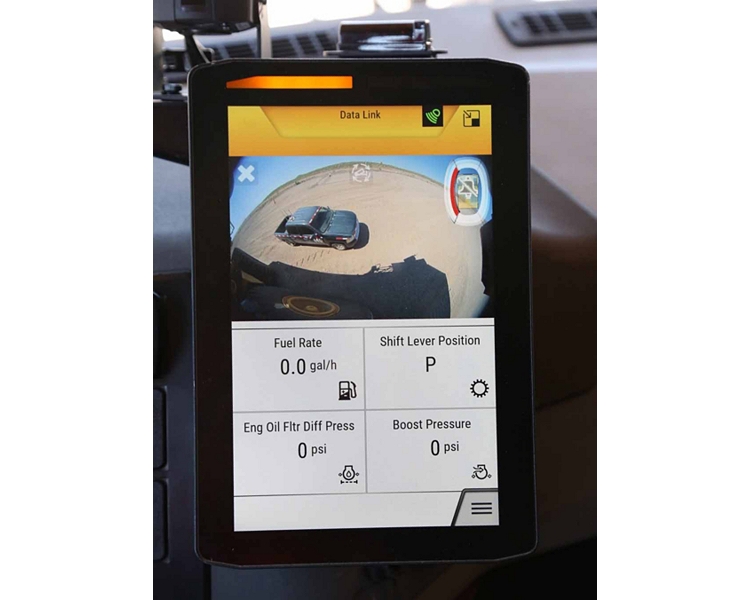

- Interactive touchscreen vehicle information display: Day/night mode; Action alarm; Quad gauge display

- Operator and trainer air suspension seats

- Operator Door Power Window

- Provision for customer accessory mounting

- Push button secure start

- Retractable front visor

- ROPS cab, insulated/sound suppressed

- Stairway and walkway access, 600 mm (24 in)

- Steering wheel, tiltable, telescopic

- Self-filling to windshield washer fluid from AC condensate

- Storage locations for operator gear

- Three point seat belt for operator seat

- Windshield wiper, intermittent control / washer

- Unitized hydraulic powered HVAC with automatic temperature control

- Ventilated operator seat

-

- Power Train

-

- 33R51 power train with standard rims

- Cat 3512E engine: Automatic engine and DEF thermal management (if applicable); Automatic low voltage idle management; Air cleaner with precleaner (two); Turbocharging (four) with air-to-air aftercooler; Mechanical Electronic Unit Injector (MEUI™-A) fuel system; Automatic starter protection; Automatic ether starting aid

- Hydraulic braking system: Automatic retarder control (ARC), adjustable and automatic; Brake release motor (towing); Engine over speed protection; Extended life brake disc material; Hill start assist/Anti roll back strategy; Oil-cooled, multi-disc (front and rear) — Service, retarding, parking, secondary; Park brake integrated with gear selector

- Transmission :Six-speed, automatic power shift with Electronic Clutch Pressure Control (ECPC); Advanced Productivity Electronic Control Strategy (APECS); Body-up reverse neutralizer; Body-up shift inhibitor; Downshift/reverse shift inhibitor; Directional shift management; Enhanced Traction Control System; Programmable top gear; Oil level sensor; Neutral coast inhibitor; Neutral start switch; Lock-up torque converter; Rear axle continuous lubrication/filtration

- Turbine air starter with air tank, air horn and automatic lubrication system

-

- Other Equipment

-

- Auxiliary "buddy" dumping quick connect

- Auxiliary connection 'user defined shutdown'

- Auxiliary steering quick connect (towing)

- eOMM

- Fast fill fuel and DEF remote fill system

- Guards for rotating components

- Hill Start Assist

- Hydraulic Filters, 1,000 hours

- Remote flash software and troubleshooting

- Secondary steering (automatic)

- Tie off points

- Tow hooks (front) and tow pin (rear)

- Sight glasses for hydraulic oils

- SOS℠ ports

- Vital Information Management System (VIMS)

-

- Cat Technology Products

-

- Cyber security

- Integrated object detection system with touchscreen display

- Tire Payload Monitoring System 2 (TPMS 2)

- Product Link™ Elite

Optional Equipment:

-

- Electrical

-

- Auxiliary rear work lights, (one) LH side

- Digital Payload Display

- LED Lighting system: Additional lighting package, Auxiliary VIMS, Body rear, Seat & park brake

- Workshop horn

-

- Truck Bodies

-

- MSD II body: 100 m3 (131 yd3)

- Dual slope body: 78 m3 (102 yd3)

- Body specific side wall and tail extensions

- Customizable body liner packages

- Body heat exhaust

- Rock ejectors

- Rear body lighting group: Directional signals, Stop/tail lights

-

- Fluids

-

- Extended Life Coolant to — 50° C (— 58° F)

-

- Operator Environment

-

- Emergency stop

- Deluxe Cab: Advanced cabin filtration system; Catwalk and handrails for rear cab access; Heated, cooled and ventilated front seat; Power right side window; Suspended companion seat; Storage tray

-

- Power Train

-

- No air – electric starter with 93-amp hour batteries (four), electric horn and automatic lubrication system

- Hydraulic braking system: Advanced ground control with Anti-lock Braking System (ABS) and Dynamic Stability Control (DSC)

- Variable speed fan drive

- Transmission: Engine pre-lubrication system; Rear axle continuous lubrication/filtration with cooler

-

- Other Equipment

-

- 2560 L (676 gal) fuel tank (non-Tier 4)

- Body heat exhaust

- Bumper towing – center pin kit

- Cold weather start (block heater)

- Communication Ar – Minestar™ radio

- Fire extinguisher, portable

- Five piece crankcase guards

- Fuel heater, fuel water separator

- Fuel tank mud guard

- Gauge, brake wear indicator

- Ground accessible fluid service center, hydraulic and coolant

- Hub odometer, kilometers

- Powered access stairway

- Rim Diffuser

- Wheel chocks

- Wireless Electronic Technician (ET)

- Working at heights protection

-

- Cat Technology Products

-

- Cruise control

- 360 degree surround view camera

- 4G cellular/satellite dual mode

- Connectivity bundle (includes: wireless operator ID, bluetooth key FOB to start)

- Driver Safety System (DSS) 4.0 Ready

- Minestar GPS

- Minestar communication group (enables: Minestar Fleet, Aux, and Truck Spotting)

- Oil Renewal System (ORS) (non-Tier 4)

- Road Analysis Control (RAC)

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.